PSA Systems

Optimized PSA Systems Solutions

UNICAT provide a complete design and build package for Pressure Swing Adsorption (PSA) systems.

From plant assessments and improvements to full new design and builds, we ensure the highest levels of efficiency and profitability through dedicated control systems and the use of premium adsorbents.

- We Innovate

- We Design

- We Build

- We Install

We have worked with customers to understand their PSA process problems and business aims with a view and focus on improving their efficiency and profitability.

We worked on innovative catalyst and process technology solutions and formed a partnership with a leading international PSA plant design and manufacturer.

This exclusive partnership is additive to UNICATs existing leading edge PSA absorbent and control system technology, helping to significantly reduce customers process problems and increase their profitability.

We Expertly Provide:

- Full design and build

- Innovative control systems

- Comprehensive engineering services

- Premium PSA Adsorbents

- Process Simulation

- Plant Assessments and Improvements

Full PSA System Build

& Design Solutions

Improved Efficiency & Profitability

Support From Comprehensive Engineering Services

Use of Industry Leading PSA Adsorbents

Customer focussed innovation – improving sustainability and profits

Our strategic business aim is constant reinvestment in catalyst and process technologies, enabling us to support hydrocarbon processors in achieving their goals.

We actively seek to understand customers' problems and process limitations, ensuring that solutions are tailored to meet specific needs.

Our innovations are not only the result of internal expertise but also strategic partnerships with customers, working together to improve customer sustainability, efficiency and profitability.

Through these partnerships UNICAT has been able to improve the operation of many PSA units, fulfilling customer’s needs and ultimately driving advancements in the industry.

Ground-breaking gas purifying and separating technology

Pressure Swing Adsorption (PSA) is a well-established gas separation process in hydrogen purification, helium purification and air separation among others. In addition to engineering, the adsorbents selected and employed in the PSA process are extremely important in determining the performance of a PSA unit.

We offer a premium range of adsorbents and a deep technical understanding in engineering PSA systems to lead our customers to the best PSA performance possible.

Our range of products remove targeted contaminants from standard:

- CO, CO2, C1-C6+ hydrocarbons

- H2S, H2O

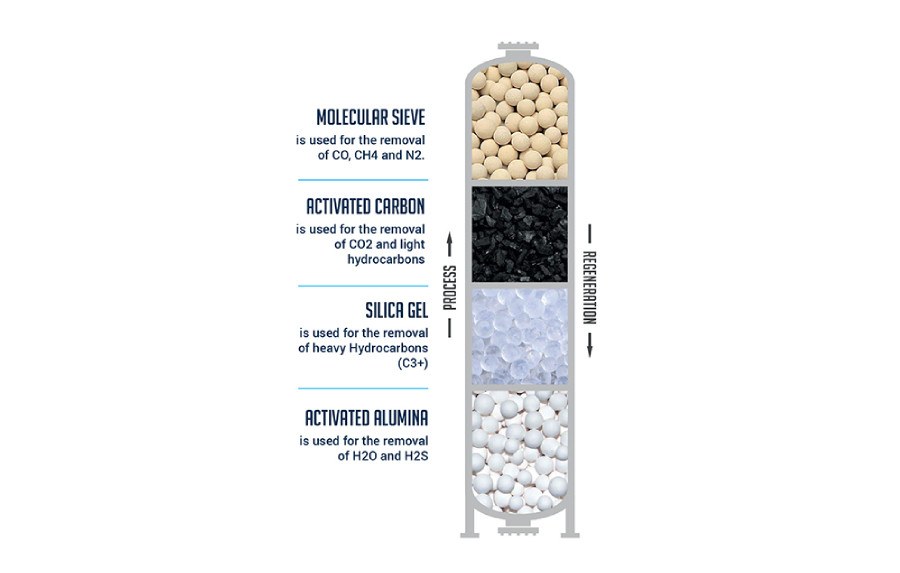

Different layers of adsorbents are used to remove targeted contaminants

There are a significant number of contaminants that require removal from a standard gas stream. Different layers of adsorbents are commonly used to remove one or more targeted contaminants.

Process steps are upflow while the regeneration steps are downflow.

PSA Benefits

- Downstream Catalyst poisoning avoided

- Benefits of Magcat® embedded with PSA result in increased SMR production, reduced Methane Slip

- Single source supplier (Catalyst, tubes, HTS, Purification, Sulfur removal & PSA)

- Significant PSA reload experience

- Responsive tech services & support

- Long Adsorbent Life

- High Purity Hydrogen Produced (99.99%)

- High hydrogen recovery (90%)

- Hydroprocessing units – Increased run time

Our services

- CO and N2 removal

- CO2, CO and H2S removal

- H2S, CS2 and CO2 removal

- H2O and heavy hydrocarbon removal

- Rapid liquid absorption

- Existing plant assessments

- Plant improvement recommendations

- Full Plant Design & Build capabilities

- Innovative Control Systems

- A complete range of Engineering Services